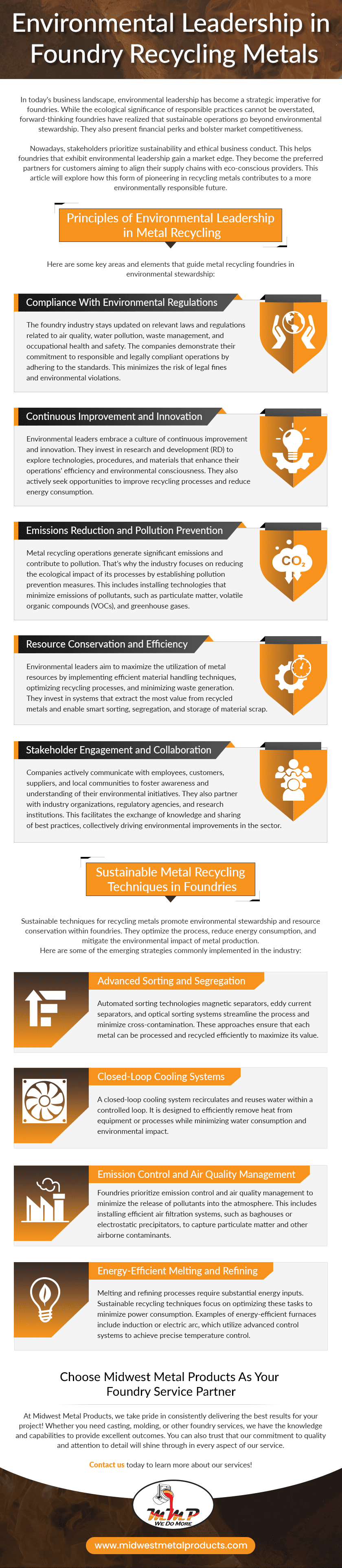

Environmental Leadership in Foundry Recycling Metals

Leave a CommentIn today’s business landscape, environmental leadership has become a strategic imperative for foundries. While the ecological significance of responsible practices cannot be overstated, forward-thinking foundries have realized that sustainable operations go beyond environmental stewardship. They also present financial perks and bolster market competitiveness.

Nowadays, stakeholders prioritize sustainability and ethical business conduct. This helps foundries that exhibit environmental leadership gain a market edge. They become the preferred partners for customers aiming to align their supply chains with eco-conscious providers. This article will explore how this form of pioneering in recycling metals contributes to a more environmentally responsible future.

Principles of Environmental Leadership in Metal Recycling

Here are some key areas and elements that guide metal recycling foundries in environmental stewardship:

Compliance With Environmental Regulations

The foundry industry stays updated on relevant laws and regulations related to air quality, water pollution, waste management, and occupational health and safety. The companies demonstrate their commitment to responsible and legally compliant operations by adhering to the standards. This minimizes the risk of legal fines and environmental violations.

Continuous Improvement and Innovation

Environmental leaders embrace a culture of continuous improvement and innovation. They invest in research and development (RD) to explore technologies, procedures, and materials that enhance their operations’ efficiency and environmental consciousness. They also actively seek opportunities to improve recycling processes and reduce energy consumption.

Emissions Reduction and Pollution Prevention

Metal recycling operations generate significant emissions and contribute to pollution. That’s why the industry focuses on reducing the ecological impact of its processes by establishing pollution prevention measures. This includes installing technologies that minimize emissions of pollutants, such as particulate matter, volatile organic compounds (VOCs), and greenhouse gases.

Resource Conservation and Efficiency

Environmental leaders aim to maximize the utilization of metal resources by implementing efficient material handling techniques, optimizing recycling processes, and minimizing waste generation. They invest in systems that extract the most value from recycled metals and enable smart sorting, segregation, and storage of material scrap.

Stakeholder Engagement and Collaboration

Companies actively communicate with employees, customers, suppliers, and local communities to foster awareness and understanding of their environmental initiatives. They also partner with industry organizations, regulatory agencies, and research institutions. This facilitates the exchange of knowledge and sharing of best practices, collectively driving environmental improvements in the sector.

Sustainable Metal Recycling Techniques in Foundries

Sustainable techniques for recycling metals promote environmental stewardship and resource conservation within foundries. They optimize the process, reduce energy consumption, and mitigate the environmental impact of metal production. Here are some of the emerging strategies commonly implemented in the industry:

Advanced Sorting and Segregation

Automated sorting technologies magnetic separators, eddy current separators, and optical sorting systems streamline the process and minimize cross-contamination. These approaches ensure that each metal can be processed and recycled efficiently to maximize its value.

Closed-Loop Cooling Systems

A closed-loop cooling system recirculates and reuses water within a controlled loop. It is designed to efficiently remove heat from equipment or processes while minimizing water consumption and environmental impact.

Emission Control and Air Quality Management

Foundries prioritize emission control and air quality management to minimize the release of pollutants into the atmosphere. This includes installing efficient air filtration systems, such as baghouses or electrostatic precipitators, to capture particulate matter and other airborne contaminants.

Energy-Efficient Melting and Refining

Melting and refining processes require substantial energy inputs. Sustainable recycling techniques focus on optimizing these tasks to minimize power consumption. Examples of energy-efficient furnaces include induction or electric arc, which utilize advanced control systems to achieve precise temperature control.

Choose Midwest Metal Products As Your Foundry Service Partner

At Midwest Metal Products, we take pride in consistently delivering the best results for your project! Whether you need casting, molding, or other foundry services, we have the knowledge and capabilities to provide excellent outcomes. You can also trust that our commitment to quality and attention to detail will shine through in every aspect of our service.

Contact us today to learn more about our services!