Engineers Guide

Engineer’s Casting Services Reference Provided by Midwest Metal Products

Engineer’s Casting Services Reference Provided by Midwest Metal Products

Fast answers to reducing costs at your company by leveraging the expertise at MMP

When you partner with MMP, you get more than castings. You get solutions to your problems. We provide better total product value using our in-house capabilities— with our castings or those you supply— to provide finishing, heat treating, and engineering support. Relieve the stress— it’s like having a metallurgist on YOUR staff!

Castings

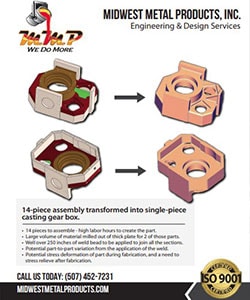

An Engineer asks: “How can I decrease parts count, maximize value, and improve reliability?”

With MMP, it may be as easy as converting labor intensive ‘Weldments’ into castings.

Click here to get more information about Castings.

Finishing Services

Our expertise lowers both risk and costs for you. Why do in-house what can be done by experts?

Click here to get more information about our Finishing services.

Heat Treating

Our on-staff metallurgists can advise you on which of our many heat treatments will best fit your specific application.

Click here to get more information about Heat Treating.

Engineering/Design

Need expert advice? Our team, led by a trained, on staff metallurgist, is the solution provider for:

- Reverse Engineering

- Weldment to casting conversions

- Models Simulations

- Solidification and flow modeling

- Prototyping to production

- Tool-less prototypes

Why is having a metallurgist onsite important?

In the casting world, it’s the difference between a house painter and Picasso. MMP’s Picasso is Joe Plunger. There are over 1,000 variables within the casting process. When foundry operations run into a problem either producing a part or heat treating, they call the expert, a metallurgist, in for a consultation. Metallurgists are highly trained professionals who are in high demand in the industry, and luckily at MMP, we have two as part of the ownership group, both working actively at the plant.

All foundries have casting challenges, called “scrap rate” in the industry. The fewer mistakes, or lower the scrap rate, the lower the cost factor in the price you pay. With metallurgists on staff, we have certified experts to plan and identify problems before they become mistakes or scrap. With metallurgical oversight, you are assured that MMP will meet or exceed any quality specification you demand. If MMP can’t meet the specification you require, we won’t even quote!